Automatic / Pneumatic Sealers

IMPAK's automatic / pneumatic impulse sealers feature controls that do not require operators to activate the seal bar by hand each cycle. These machines are operated either by setting the seal bar to close at regular intervals (AIS Series) or by using a foot pedal to trigger the seal bar to close pneumatically.

The MP Series medical tabletop impulse sealers are perfect for budget and space-conscious bag sealing applications and are ruggedly built to provide years of trouble-free service. Standard controls include a glycerin filled gauge, pressure regulator, separate heat and cool timers and tap to start foot pedal. The machines are powder coated and easy to clean. Analog controls provide simple operation where validation is not a requirement. A bottom flange allows for this bag sealing unit to be mounted horizontally or vertically. Available in 15”, 20” and 25” seal lengths.

NOTICE: Machines are built to order in the USA. Please call for current lead times.

High Volume "Seal Only" Units

The workhorses of IMPAK’s tabletop heat sealing line of products, ideal for medium to high volume use. These units will provide years of superior service. Available seal lengths of 21", 26", 31", 36", 41", 51", and 61". Standard features include:

- High-grade stainless steel body

- Heavy duty anodized aluminum frame

- Upper and lower heating elements

- Color touch screen control

- Exclusive built-in safety seal bar

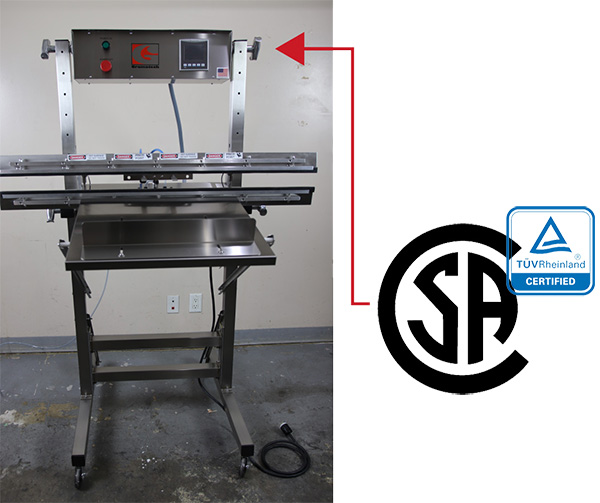

CSA Certification Announcement

IMPAK is proud to partner with a major Multi-National Pharmaceutical Company and to have been granted a CSA Certification for its industry leading line of Gramatech Vacuum Heat Sealers. “We are now ready to offer CSA registration as an option to our industry leading line of Gramatech Sealers,” according to Rajib Hasan, Managing Director, Machine Group.

As the company General Manager Kevin Cullen has said, “We are very proud of the machinery we have built to CSA standards.” The story below written by Alan Masnek, our resident Certified Packaging Professional (CPPL) and graduate of University of Wisconsin – Stout, illustrates the steps that were taken to design, develop and produce a piece of equipment for pharma MNC. This particular MNC is just one of the many top medical manufacturing firms we are proud to have produced product for. [ see full article ]

The following video is of the vacuum-version of the Workhorse. See those units here. The seal-only version does not have nozzles or vacuum capabilities.