Vacuum & Heat Sealers

IMPAK Corporation offers an extensive line of sealing equipment, plus the ability to repair and upgrade existing machinery for better performance and greater control. To learn more about our machine capabilities and custom-builds, Contact IMPAK

"While we thrive at underpromising and overdelivering to our customers when it comes to meeting all QA checklists, we are careful to confirm that all equipment is thoroughly inspected before it ships."

- IMPAK Machinery Group Managing Director

Choose from vacuum sealers, continuous band sealers, chamber vacuum sealers, portable handheld sealers, large frame circular sealers, tube sealers, cup sealers, and more. Select models come with a nitrogen flush option. Tabletop clean room options available as well as free-standing machines with standard seal lengths including 36", 48", 60", 72", 84", 96", 110". Looking for a specific control system? We can outfit our machines using systems like Siemens, Allen-Bradley, or Unitronic controllers.

Sealer Safety

As a manufacturer of Industrial Equipment - Safety is a top concern for us. We have a variety of standard and optional safety features to ensure less risk to operators.

IMPAK is a company that will produce and support all other major heat sealing manufacturers - including perhaps most important companies that are no longer in business or companies that have decided to no longer produce a specific product line.

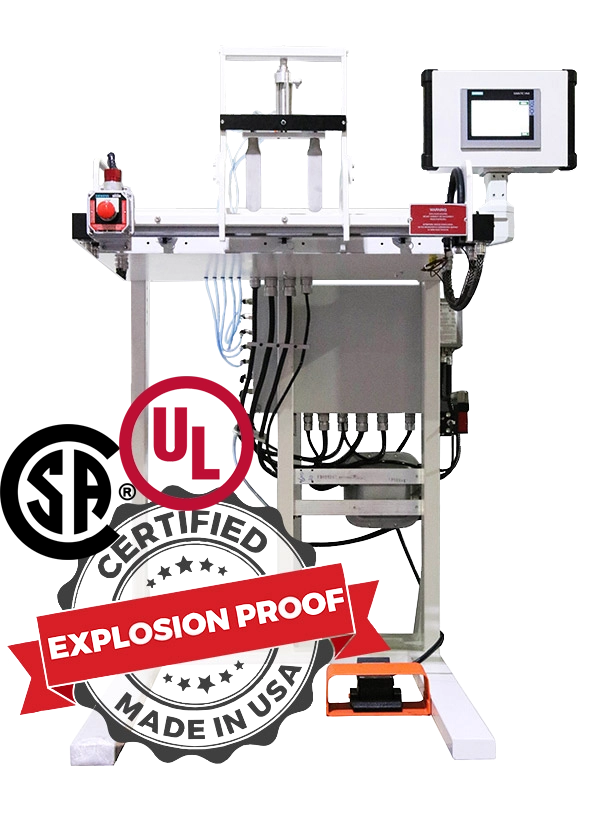

Need an Explosion-Proof Sealer for HazLoc Settings? Learn More Here

Case Study: Make Up For Ever / Sephora

When Quality Is Paramount & Time Is of the Essence

Exclusive cosmetic samples for VIP members at Sephora’s first cosmetic convention, SEPHORA, held in Los Angeles. World-renowned Make Up For Ever entrusted IMPAK Corporation to assemble, package and vacuum seal their exclusive product line for this event. 8” x 10” PAKVF 3.5 mil Metallized Pouches were chosen to package three samples along with a piece of cardstock with the company’s logo on it. Using the CHTC-280 Chamber Vacuum Sealer, the packaging was sealed airtight, allowing the distinct logo to pop and create an embossed look. The embossed logo is an alternative to price graphics while really making the package stick out to consumers on the shelf. Sealing the packages with this sealer also ensures one of the tightest possible seals, perfect for making the contents of the bag immobile during transport.

IMPAK was key in helping implement the release of this product with a rapid, 2-week turnaround, start to finish! Typically, when packaging & sealing for a customer, we require a minimum 5-day wait between receiving the product and packaging/sealing. Due to the urgent matter, we were able to supply our customer 250 completed pieces consecutively for 5 days, completing a total of 1250 ready to go products for the event.

IMPAK manufactures quality sealers in the USA and

provides competitive pricing for our machines.

- Band Sealers

- Chamber Vacuum Sealers

- Code Printer

- Cup & Tray Sealers

- Custom Heat Sealers

- Explosion-Proof Sealers

- Filling Equipment

- Foot Pedal Sealers

- Heavy Duty Impulse Sealers

- Home/Lab Vacuum Sealers

- MasterWeld 1200

- PikNPak System

- Portable Sealers

- Pouch Openers

- Refurbished Sealers

- Rental Sealers

- Sealing Clips

- Spare Parts

- Tabletop Impulse Sealers

- Tube Sealers

- Vacuum Sealers (Nozzle-Style)

- Validation-Ready Sealers