What Is "Kraft"?

You may see several pouches on our site decribed as "kraft" bags or having "kraft" as their color. These pouches made primarily of kraft paper, which many people associate with brown paper bags, and which has a natural, rustic look and feel. The term is derived from the German word Kraft, meaning strength, which refers to the material's durability; it was so named by the German who invented the process in 1879, Carl F. Dahl. When a sealant and/or foil barrier is laminated to kraft paper, the resulting material can be used to make bags that can be heat sealed and that provide a potent barrier against moisture and oxygen, while still having a distinctly appealing look.

How is kraft paper made?

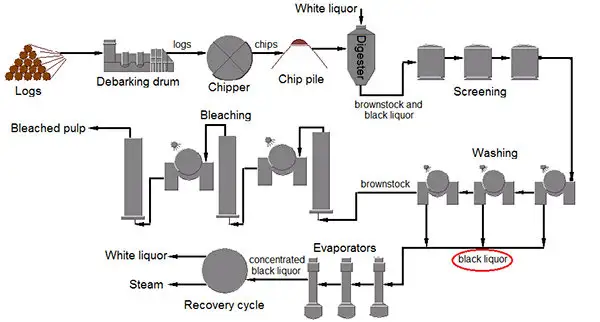

The Kraft process is a method used in the paper industry to convert wood into wood pulp, which is a primary ingredient for making paper. Here's how it works:

- Wood Preparation: Initially, logs or wood chips are debarked and chipped into small pieces. The type of wood used can vary, but softwood, like pine or spruce, is commonly preferred due to its long fibers, which are essential for making strong paper.

- Cooking: The wood chips are then placed into large vessels called digesters, where they are cooked under high temperature and pressure in a mixture of water and chemicals. The most common chemicals used are sodium hydroxide (NaOH) and sodium sulfide (Na2S), collectively known as "white liquor." This process breaks down the lignin, a natural adhesive that holds the wood fibers together, and separates the lignin from the cellulose fibers.

- Pulping: Once the cooking process is complete, the resulting mixture, known as "black liquor," contains dissolved lignin, cellulose fibers, and other organic materials. The black liquor is then separated from the pulp fibers through a series of washing and screening processes.

- Bleaching (Optional): Depending on the desired quality and color of the final paper product, the pulp may undergo a bleaching process to remove any remaining lignin and brighten the fibers. This typically involves additional chemical treatments or the use of hydrogen peroxide or chlorine compounds.

- Papermaking: The resulting pulp, now clean and ready for paper production, is mixed with water to form a slurry. This slurry is then spread onto a moving mesh screen, where water drains away, leaving behind a thin layer of fibers. This layer is then pressed, dried, and rolled to form large rolls of paper.

Image courtesy of ReasearchGate

The Kraft process is widely used in the paper industry due to its efficiency in breaking down lignin and producing strong, high-quality pulp suitable for various paper grades. Additionally, the process is relatively environmentally friendly compared to older methods, as it allows for the recovery and reuse of chemicals and energy from the black liquor.